AA Elevator Bucket

Super Tough Nylon

This versatile bucket comes in a wide range of materials to meet any needs you may have. They work especially well in high-throughput elevators that handle industrial-type materials. Whatever your elevator handles, there is a bucket to match it in the AA series.

Why Nylon?

The toughest of all the non-metallic materials, nylon is rigid and abrasion-resistant. Compared to other plastics, nylon has a greater heat resistance and is non-sparking and non-corrosive. This is the perfect material if your buckets need to stay strong under extreme abuse or if you just want a material that will last longer

Features

- Prime virgin, impact-modified nylon

- Choose from 12 sizes

- Recommended capacity is 75% of gross capacity

- Can be intermixed with existing buckets

Applications

- Foundry Sand

- Sand and Gravel

- Coal

- Fertilizers

- Clay

- Salt

Additional Materials

Measurement Conversion: Imperial Metric

| Size (Nominal) Inches |

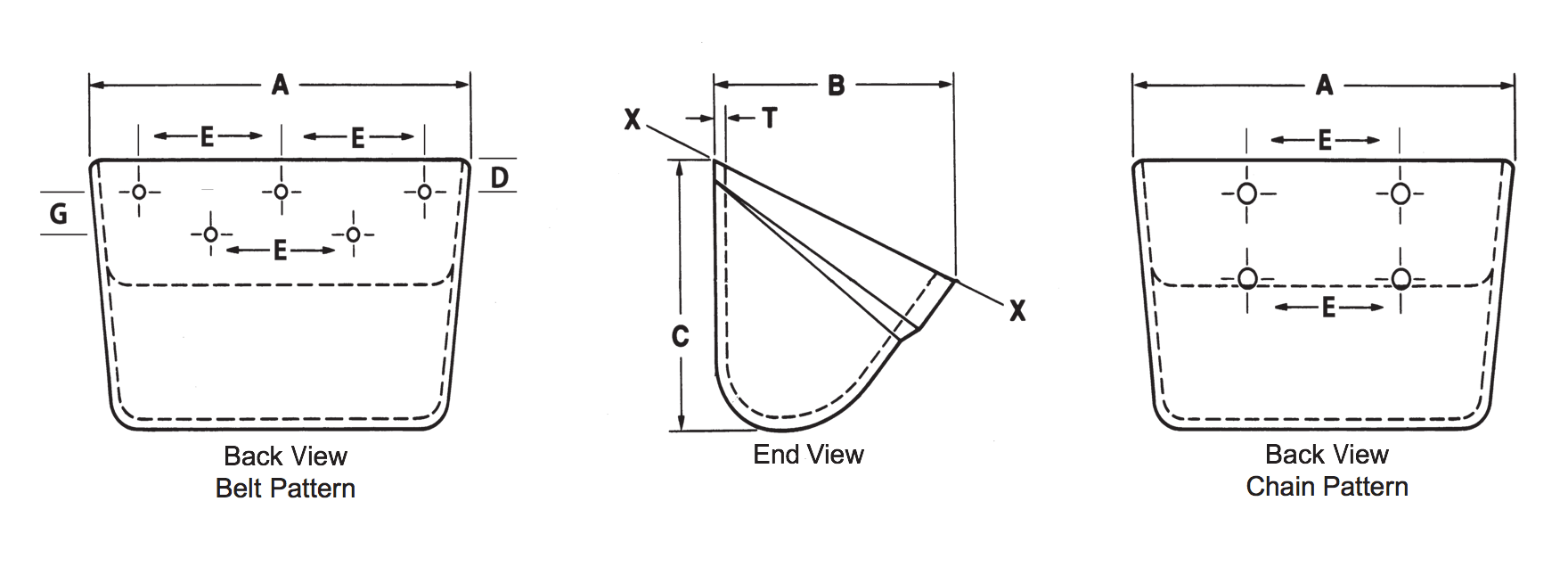

Dimension-Actual (Inches) Tolerance A, B & C ± .25" T ± .03125" |

Hole Drilling-Standard (Inches) Holes Drilled .03125" Oversize |

Capacity ■ Tolerance ± 3% |

Approx. Weight (Pounds) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length A | Proj. B | Depth C | Thickness T | Center to Center E | Number of Holes | Bolt Diameter | Distance Down D | Between Rows G | Gross X-X | Usable | ||||

| Cu. In. | Cu. Ft. | Cu. In. | Cu. Ft. | |||||||||||

| 4 X 2-3/4 | 4-1/4 | 3 | 3-1/8 | 3/16 | 2-5/16 | 2 | 1/4 | 3/4 | -- | 15.3 | .009 | 11.5 | .007 | 0.24 |

| 5 X 3-1/2 | 5-3/8 | 3-3/4 | 3-3/4 | 1/4 | 3-3/16 | 2 | 1/4 | 1 | -- | 30.2 | .017 | 22.6 | .013 | 0.44 |

| 6 X 4 | 6-3/8 | 4-1/4 | 4-1/2 | 1/4 | 4-3/8 | 2 | 1/4 | 1 | -- | 50.5 | .029 | 37.9 | .022 | 0.60 |

| 7 X 4-1/2 | 7-3/8 | 4-3/4 | 5 | 1/4 | 2-1/2 | 3 | 1/4 | 1 | -- | 77.8 | .045 | 58.4 | .034 | 0.83 |

| 8 X 5 | 8-3/8 | 5-1/4 | 5-1/2 | 1/4 | 3 | 5 | ✽ 1/4 | 7/8 | 1 | 105.0 | .061 | 78.8 | .046 | 1.16 |

| 10 X 6 | 10-1/2 | 6-1/2 | 6-5/8 | 1/4 | 3-1/2 | 5 | ✽ 1/4 | 7/8 | 1 | 198.5 | .115 | 148.9 | .086 | 1.72 |

| 12 X 7 | 12-1/2 | 7-5/8 | 7-3/4 | 3/8 | 4-1/2 | 5 | ✝ 5/16 | 7/8 | 1 | 319.6 | .185 | 239.7 | .139 | 2.69 |

| 14 X 7 | 14-1/2 | 7-5/8 | 7-3/4 | 3/8 | 4 | 7 | 5/16 | 7/8 | 1 | 385.4 | .223 | 289.1 | .167 | 3.05 |

| 14 X 8 | 14-1/2 | 8-7/8 | 8-3/4 | 1/2 | 4 | 7 | 5/16 | 7/8 | 1 | 494.6 | .286 | 371.0 | .215 | 4.30 |

| 16 X 8 | 16-1/2 | 8-7/8 | 8-3/4 | 1/2 | 4-1/2 | 7 | ✝ 5/16 | 7/8 | 1 | 576.4 | .334 | 432.3 | .251 | 4.89 |

| 18 X 8 | 18-1/2 | 8-7/8 | 8-3/4 | 1/2 | 5 | 7 | ✝ 5/16 | 7/8 | 1 | 653.9 | .378 | 490.4 | .284 | 5.46 |

| 18 X 10 | 18-1/2 | 10-3/4 | 10-3/4 | 1/2 | 5 | 7 | ✝ 5/16 | 7/8 | 1 | 1001.1 | .579 | 750.8 | .434 | 7.97 |

■ Tapco recommends using gross X .75, for usable capacity

✽ Buckets can be drilled for .25" or .3125" bolts, please specify. .25" is standard.

✝ Buckets can be drilled for .3125" or .375" bolts, please specify. .3125" is standard.

Style:

AA

Design:

Centrifugal discharge.

Material:

Prime Virgin Impact Modified Nylon.

Method of Manufacture:

Injection molded.

Color:

Gray.

Temperature Range:

-40° F to + 275° F. (-40° C to +135° C).

Flammability:

The impact modifi ed nylon used in Tapco buckets is termed “slow burning”. It has been tested under Underwriters’ Laboratory Bulletin No. 94 HB. The primary toxic product of combustion is carbon monoxide.

Standard Drilling:

No charge for standard belt or chain drillings when order totals 50 or more pieces of the same size. Contact Tapco for quotation on orders of less than 50 and/or special drill pattern requirements.

Special Drilling:

Available on request. Contact Tapco for recommendations.

Venting:

Available on request. Contact Tapco for recommendations.

Usable Capacity:

Tapco recommends using 75% of gross, (100%) capacity.

Spacing:

A common spacing would be nominal projection plus 4", however both closer and greater spacings may be used depending upon the application.

Interchangeability:

Can be intermixed with existing metallic or nonmetallic buckets. Some care should be taken that the leg does not become too far out of balance. Bucket projection varies by manufacturer and material. Check elevator for proper clearances. Contact Tapco for recommendations.

Installation:

Fanged elevator bolts and nylon insert lock nuts are recommended for pulleys 6" in diameter and over. No. 3, Eclipse slotted head elevator bolts are recommended for pulleys under 6" in diameter. Flat steel washers must be placed inside the bucket under the nuts. Check elevator for proper clearances.

FDA Status:

Impact modifi ed nylon does not meet requirements for FDA approval.

Recommendations:

AA nylon buckets are ideal for use with foundry sand, gravel, coal, fertilizer, clay salt, and many other industrial materials.

Limitations:

Nylon buckets should not be used on the following: (1) Materials over 275° F/ 135° C, (2) Sharp edged materials such as crushed glass or oyster shells, (3) Some large dense materials such as stone and ores.

Caution:

Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion. Tapco nylon buckets can be ignited and will burn from improper welding and cutting.

Important:

When elevating certain materials that harden or setup with moisture, a Tapco metallic digger bucket should replace every 10th nylon bucket. In some instances ductile iron AA style buckets (See page 43) will not have suffi cient projection to protect the nylon bucket. It will be necessary to use a pad or spacer behind the digger bucket. Contact Tapco for recommendations.