AA Elevator Bucket

Ductile Iron

This versatile bucket comes in a wide range of materials to meet any needs you may have. They work especially well in high-throughput elevators that handle industrial-type materials. Whatever your elevator handles, there is a bucket to match it in the AA series.

Why Ductile Iron?

Iron buckets should be substituted for nonmetallic buckets when the heat becomes too excessive or when the bucket elevator carries extremely sharp products. They are resistant to wear, impact and corrosion, with a high strength-to-weight ratio.

Features

- Cast Ductile Iron

- Choose from 12 sizes

- Recommended capacity is 75% of gross capacity

- Can be intermixed with existing buckets

Applications

- Stone

- Foundry Sand

- Sand and Gravel

- Coal

- Fertilizers

- Clay

- Salt

Additional Materials

Measurement Conversion: Imperial Metric

| Size (Nominal) Inches |

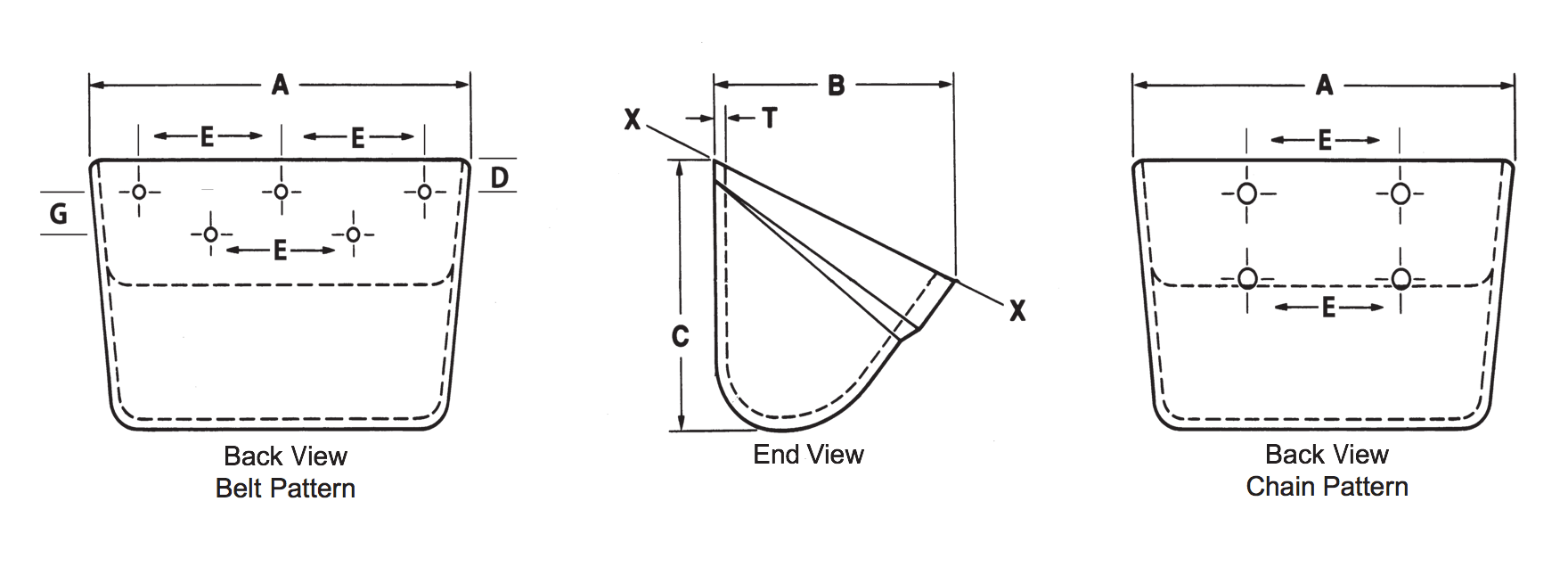

Dimension-Actual (Inches) Tolerance A, B & C ± .25" T ± .03125" |

Hole Drilling-Standard (Inches) Holes Drilled .03125" Oversize |

Capacity ■ Tolerance ± 3% |

Approx. Weight (Pounds) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length A | Proj. B | Depth C | Thickness T | Center to Center E | Number of Holes | Bolt Diameter | Distance Down D | Between Rows G | Gross X-X | Usable | ||||

| Cu. In. | Cu. Ft. | Cu. In. | Cu. Ft. | |||||||||||

| 4 X 2-3/4 | 4 | 2-15/16 | 3 | 5/32 | 2-5/16 | 2 | 1/4 | 3/4 | -- | 15.3 | .009 | 11.5 | .007 | 1.5 |

| 5 X 3-1/2 | 5 | 3-11/16 | 3-3/4 | 11/64 | 3-3/16 | 2 | 1/4 | 3/4, 1 | -- | 30.2 | .017 | 22.6 | .013 | 2.4 |

| 6 X 4 | 6 | 4-3/16 | 4-1/4 | 3/16 | 4-3/8 | 2 | 1/4 | 1 | -- | 50.5 | .029 | 37.9 | .022 | 3.3 |

| 7 X 4-1/2 | 7 | 4-11/16 | 4-3/4 | 3/16 | 2-1/2 | 3 | 1/4 | 1 | -- | 77.8 | .045 | 58.4 | .034 | 5.1 |

| 8 X 5 | 8 | 5-1/4 | 5-1/2 | 3/16 | 3 | 5 | ✽ 1/4 | 7/8 | 1 | 105.0 | .061 | 78.8 | .046 | 6.3 |

| 12 X 5 | 12 | 5-1/4 | 5-1/2 | 13/64 | 4-1/2 | 5 | ■ 5/16 | 7/8 | 1 | 166.9 | .096 | 125.2 | .072 | 8.7 |

| 15 X 5 | 15 | 5-1/4 | 5-1/2 | 7/32 | 4 | 7 | 5/16 | 7/8 | 1 | 209.9 | .122 | 157.4 | .092 | 11.6 |

| 19 X 5 | 19 | 5-1/4 | 5-1/2 | 7/32 | 4 | 9 | 5/16 | 7/8 | 1 | 276.4 | .160 | 207.3 | .120 | 15.3 |

| 9 X 6 | 9 | 6-1/4 | 6-1/4 | 13/64 | 3 | 5 | ✽ 1/4 | 7/8 | 1 | 159.9 | .093 | 119.9 | .070 | 8.9 |

| 10 X 6 | 10 | 6-1/4 | 6-1/4 | 13/64 | 3-1/2 | 5 | ✽ 1/4 | 7/8 | 1 | 198.5 | .115 | 148.9 | .086 | 10.6 |

| 11 X 6 | 11 | 6-1/4 | 6-1/4 | 7/32 | 4 | 5 | ✽ 1/4 | 7/8 | 1 | 221.8 | .128 | 166.4 | .096 | 10.9 |

| 12 X 6 | 12 | 6-1/4 | 6-1/4 | 7/32 | 4-1/2 | 5 | ✝ 5/16 | 7/8 | 1 | 233.1 | .135 | 174.8 | .101 | 11.3 |

| 12 X 7 | 12 | 7-5/16 | 7-1/4 | 1/4 | 4-1/2 | 5 | ✝ 5/16 | 7/8 | 1 | 319.6 | .185 | 239.7 | .139 | 13.8 |

| ▲ 12 X 7 HD | 12 | 7-5/16 | 7-1/4 | 5/16 | 4-1/2 | 5 | ✝ 5/16 | 7/8 | 1 | 319.6 | .185 | 239.7 | .139 | 16.5 |

| 14 X 7 | 14 | 7-5/16 | 7-1/4 | 1/4 | 4 | 7 | 5/16 | 7/8 | 1 | 385.4 | .223 | 289.1 | .167 | 18.1 |

| 15 X 7 | 15 | 7-5/16 | 7-1/4 | 1/4 | 4 | 7 | 5/16 | 7/8 | 1 | 401.5 | .232 | 301.1 | .174 | 19.2 |

| 16 X 7 | 16 | 7-5/16 | 7-1/4 | 1/4 | 4-1/2 | 7 | ✝ 5/16 | 7/8 | 1 | 428.1 | .248 | 321.1 | .186 | 19.9 |

| 14 X 8 | 14 | 8-7/16 | 8-1/2 | 19/64 | 4 | 7 | 5/16 | 7/8 | 1 | 494.6 | .286 | 371.0 | .215 | 25.4 |

| 16 X 8 | 16 | 8-7/16 | 8-1/2 | 19/64 | 4-1/2 | 7 | ✝ 5/16 | 7/8 | 1 | 576.4 | .334 | 432.3 | .251 | 26.3 |

| 18 X 8 | 18 | 8-7/16 | 8-1/2 | 21/64 | 5 | 7 | ✝ 5/16 | 7/8 | 1 | 653.9 | .378 | 490.4 | .284 | 33.7 |

| 20 X 8 | 20 | 8-7/16 | 8-1/2 | 21/64 | 4 | 9 | 5/16 | 7/8 | 1 | 757.3 | .438 | 568.0 | .329 | 34.6 |

| 24 X 8 | 24 | 8-7/16 | 8-1/2 | 11/32 | 5 | 9 | 5/16 | 7/8 | 1 | 901.7 | .522 | 676.3 | .392 | 47.0 |

| 18 X 10 | 18 | 10-9/16 | 10-1/2 | 11/32 | 5 | 7 | ✝ 5/16 | 7/8 | 1 | 1001.1 | .579 | 750.8 | .434 | 43.6 |

▲ The HD bucket has an extra heavy duty front lip for severe applications.

■ Tapco recommends using gross X .75, for usable capacity

✽ Buckets can be drilled for .25" or .3125" bolts, please specify. .25" is standard.

✝ Buckets can be drilled for .3125" or .375" bolts, please specify. .3125" is standard.

Style:

AA

Design:

Centrifugal discharge.

Material:

Ductile Iron.

Method of Manufacture:

Cast.

Color:

Gray.

Temperature Range:

-60°F to + 800 °F/-51° C to + 426 °C.

Standard Drilling:

No charge for standard belt or chain drillings when order totals 50 or more pieces of the same size. Contact Tapco for quotation on orders of less than 50 and/or special drill pattern requirements.

Venting:

Available on request. Contact Tapco for recommendations.

Usable Capacity:

Tapco recommends using 75% of gross, (100%) capacity.

Spacing:

A common spacing would be nominal projection plus 4", however both closer and greater spacings may be used depending upon the application.

Interchangeability:

Can be intermixed with existing metallic or nonmetallic buckets. Some care should be taken that the leg does not become too far out of balance. Bucket projection varies by manufacturer and material. Check elevator for proper clearances. Contact Tapco for recommendations.

Installation:

Fanged elevator bolts and nylon insert lock nuts are recommended for pulleys 6" in diameter and over. No. 3, Eclipse slotted head elevator bolts are recommended for pulleys under 6" in diameter. Flat steel (Fender) washers must be placed inside the bucket under the nuts. Check elevator for proper clearances.

Recommendations:

AA ductile iron buckets are ideal for use with foundry sand, and gravel, coal, fertilizer, clay, salt, and many other industrial materials.

Caution:

Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion.