Super EuroBucket®

Super Tough Nylon

Designed to fit in elevators using Super Starco, Jet and other European-manufactured buckets, the Super EuroBucket can seamlessly replace your current buckets to immediately improve performance. Their superior durability will reduce your costs, and since their design allows them to be stackable, you will save on shipping costs.

Why Nylon?

The toughest of all the non-metallic materials, nylon is rigid and abrasion-resistant. Compared to other plastics, nylon has a greater heat resistance and is non-sparking and non-corrosive. This is the perfect material if your buckets need to stay strong under extreme abuse or if you just want a material that will last longer

Features

Prime virgin, impact-modified nylon

Choose from 10 sizes

Designed to replace Super Starco, Jet and other European bucket styles

Outstanding impact and abrasion resistance

Extraordinarily tough

More rigid than polyethylene or urethane

Better heat resistance

Applications

- Soybeans

- Fertilizers

- Salt

- Sand

- Chemicals

- Rough and Abrasive Products

Additional Materials

Measurement Conversion: Imperial Metric

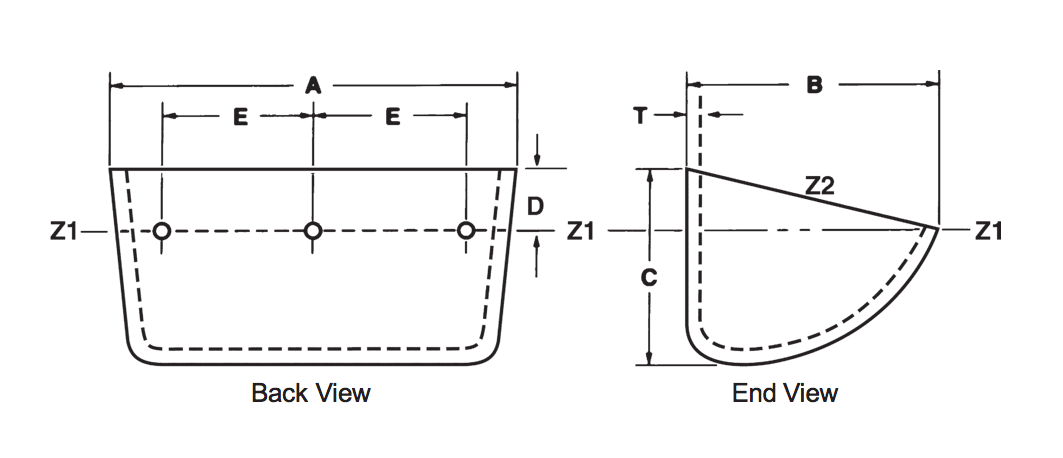

| Size (Nominal) Inches |

Dimension-Actual (Inches) Tolerance A, B, C ± .125" G, T ± .015625" |

Hole Drilling-Standard (Inches) | Capacity (Cubic Inches) Tolerance ± 3% |

Spacing (Buckets/Inches) Between Buckets |

Weight (Pounds) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length A | Proj. B | Depth C | Thickness T | Center to Center E | No. of Holes | Bolt Dia. | Hole Dia. | Distance Down D | Each (Average) | Per Carton (Average) | Number Per Carton | ||||

| Z2 | Z1 | ||||||||||||||

| 4 X 3-1/2 | 4-3/8 | 3-3/4 | 2-7/8 | 7/32 | 2 | 2 | 5/16 | 11/32 | 7/8 | 22.9 | 16.5 | 3 | 0.29 | 6.6 | 20 |

| 5 X 4-1/2 | 5-3/8 | 5 | 3-3/4 | 7/32 | 2-3/4 | 2 | 5/16 | 11/32 | 1-1/8 | 54 | 39.9 | 4 | 0.55 | 12.1 | 20 |

| 5-1/2 X 5 | 6 | 5 | 3-3/4 | 1/4 | 2-3/4 | 2 | 5/16 | 11/32 | 1-1/8 | 58.3 | 43.2 | 4 | 0.59 | 12.7 | 20 |

| 7 X 5-1/2 | 7-5/8 | 6-3/16 | 4-5/8 | 5/16 | 3-15/16 | 2 | 5/16 | 11/32 | 1-5/16 | 116.2 | 86.9 | 5 | 1.10 | 24.1 | 20 |

| 8 X 5-1/2 | 8-7/16 | 6-3/16 | 4-5/8 | 5/16 | 3-15/16 | 2 | 5/16 | 11/32 | 1-5/16 | 129.5 | 97.1 | 5 | 1.12 | 25.2 | 20 |

| 9 X 6-1/2 | 9-11/16 | 6-5/8 | 4-15/16 | 5/16 | 4-3/4 | 2 | *3/8 | 13/32 | 1-3/8 | 172.0 | 128.9 | 5 | 1.56 | 32.3 | 20 |

| 11 X 6-1/2 | 11-5/8 | 6-3/4 | 5-5/16 | 5/16 | 3-3/16 | 3 | *3/8 | 13/32 | 1-5/8 | 235.5 | 180.2 | 6 | 1.89 | 40.5 | 20 |

| 12 X 7 | 12-7/16 | 7-9/16 | 5-5/8 | 5/16 | 3-15/16 | 3 | *3/8 | 13/32 | 1-5/8 | 295.0 | 221.5 | 6 | 2.49 | 52.1 | 20 |

| 13 X 8-1/2 | 13-5/8 | 9-3/16 | 6-7/8 | 3/8 | 4-3/4 | 3 | 3/8 | 13/32 | 2-1/8 | 475.3 | 356.6 | 7 | 3.95 | 63.3 | 15 |

| 14-1/2 X 8-1/2 | 15-1/4 | 9-3/16 | 6-7/8 | 3/8 | 3-9/16 | 4 | 3/8 | 13/32 | 2-1/8 | 536.2 | 403.0 | 7 | 4.32 | 70.0 | 15 |

Standard Bolt Holes Drilled on the Z1 (Water Level) Line ± (6.0mm) ± .25"

Style:

Super EuroBucket

Design:

High speed centrifugal discharge.

Material:

Prime virgin impact modified nylon.

Method of Manufacture:

Injection molded.

Color:

Gray.

Temperature Range:

-40°F to + 275°F/-40°C to + 135°C.

Flammability:

The impact modified nylon used in Tapco buckets is termed “slow burning”. It has been tested under Underwriters’ Laboratory Bulletin No. 94 HB. The primary toxic product of combustion is carbon monoxide.

Standard Drilling:

No Charge.

Special Drilling:

Any pattern and hole diameter can be provided at minimal cost.

Venting:

Available for special applications. Contact Tapco for recommendations.

Usable Capacity:

Net or usable capacity could range from 10% to 20% above water level. For engineering purposes Tapco recommends using WL (Water Level) + 10% for usable capacity.

Interchangeability:

Can be intermixed with existing steel or nonmetallic buckets. Some consideration should be given to balance. Bucket projection varies by manufacturer and material. Check elevator for proper clearances. Contact Tapco for recommendations.

Installation:

Tapco fanged elevator bolts and nylon insert lock nuts are recommended for installation. Flat steel washers must be placed inside the bucket under the nuts. DIN bolts and/or domed washers are not recommended. Check leg for proper clearances.

FDA Status:

Impact modified nylon does not meet requirements for FDA approval.

UV Resistance:

No UV (ultraviolet) stabilizers are added to Tapco buckets because most elevator buckets are enclosed in casings. Tapco buckets should not be exposed to direct sunlight for extended periods of time.

Recommendations:

Nylon buckets are extremely strong. They are unsurpassed in rough or severe service elevators. The outstanding abrasion resistant characteristics make this an excellent bucket for grain, soybeans, feeds, fertilizer, chemicals, sand and other freeflowing products.

Limitations:

Nylon buckets should not be used in the following: (1) Materials over 275°F/135°C. (2) Large dense material such as gravel and ore over 3/8" diameter. (3) Some sharp sluggish materials such as large glass cullet or oyster shells.

Caution:

Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion. Nylon buckets can be ignited and will burn from improper welding and cutting.

Important:

When elevating certain materials that harden or set up with moisture, a Tapco steel digger bucket should replace every 10th nylon bucket. Contact Tapco for recommendations.