CC Digger Elevator Bucket

Fabricated Steel

The heavy-gauge construction, reinforced corner braces and double thick lip all work together in tandem to aid in breaking up material in the boot section of a bucket elevator. The sturdy build of this bucket make it both more effective in scooping resistant material and a durable, long-lasting choice for your elevator.

Why Steel?

Steel buckets should be substituted for nonmetallic buckets when the heat becomes too excessive or when the bucket elevator carries extremely sharp products.

Features

- Heavy Gauge Construction

- Reinforced Corner Braces and Double Thick Lip Designed to Aid in Breaking Up Material in the Boot Section of the Bucket Elevator

- Available in Stainless Steel and Carbon Steel

Applications

- Grains

- Feeds

- Fertilizers

- Sugar

- Salt

- Sand

- Seeds

- Cement

- Mineral Mixes

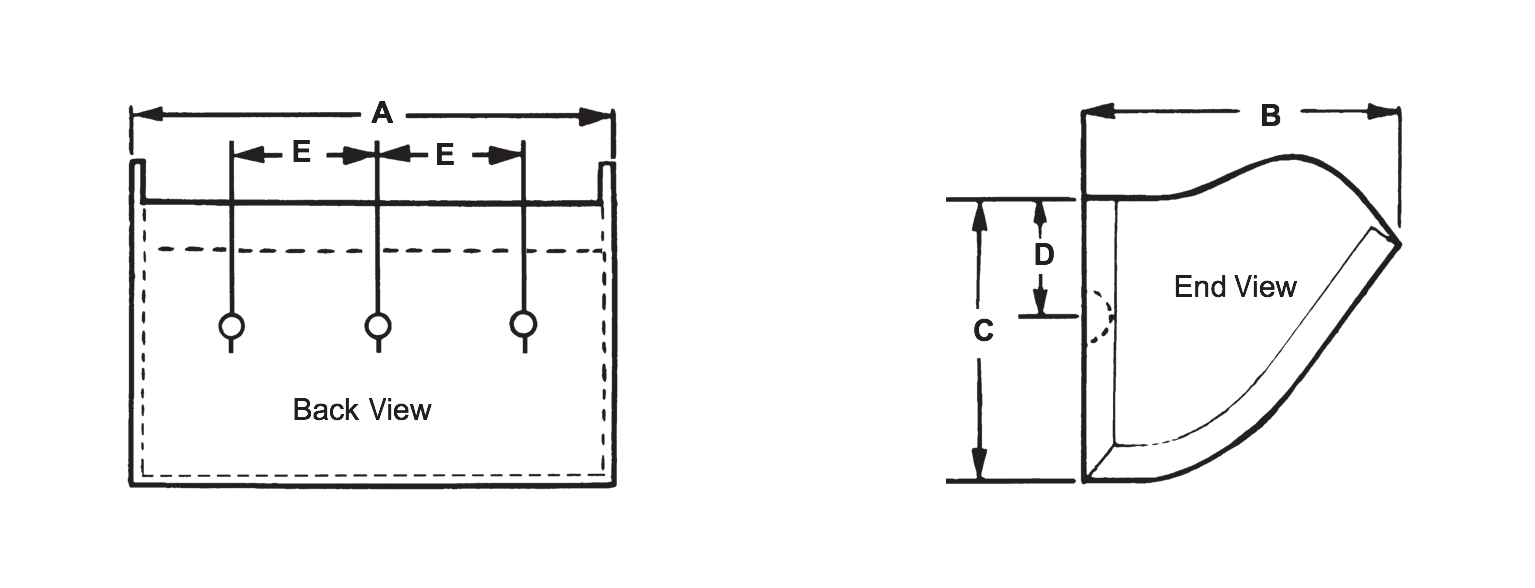

Measurement Conversion: Imperial Metric

| Size (Nominal) Inches |

Dimension-Actual (Inches) Tolerance A, B & C ± .25" |

Drilling-Standard (Inches) Holes Drilled .0625" Oversize |

Capacity ■ Tolerance ± 3% |

Carbon Steel Weight | Stainless Steel Weight | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length A | Proj. B | Depth C |

Gauge Carbon | Gauge Stainless | Hole Shape | Distance Down D |

Center to Center E |

Number of Holes | Bolt Diam. | WL | WL + 10% | |||||

| Cu. In. | Cu. Ft. | Cu. In. | Cu. Ft. | |||||||||||||

| 3 X 2 | 3-1/2 | 2-5/8 | 2-1/16 | 12 | 14 | Round | 7/8 | 1-3/4 | 2 | .25 | 6.0 | .0035 | 6.6 | .0038 | 1.55 | 1.40 |

| 4 X 3 | 4-1/2 | 3-5/8 | 3-1/16 | 12 | 14 | Slotted | 7/8 | 2-1/4, 2-1/2 | 2 | .25 | 16.8 | .0097 | 18.5 | .0107 | 2.16 | 1.60 |

| 5 X 4 | 5-1/2 | 4-3/4 | 4-1/16 | 12 | 14 | Round | 1-1/4 | 3-3/16 | 2 | .25 | 35.8 | .0207 | 39.4 | .0228 | 2.47 | 2.00 |

| 6 X 4 | 6-1/2 | 4-3/4 | 4-1/16 | 12 | 14 | Slotted | 1-1/4 | 4-3/8, 4-1/2 | 2 | .25 | 43.3 | .0251 | 47.6 | .0276 | 3.33 | 2.10 |

| 7 X 4 | 7-1/2 | 4-3/4 | 4-1/16 | 12 | 14 | Slotted | 1-1/4 | 2-11/16, 2-5/8 | 3 | .25 | 49.7 | .0288 | 54.7 | .0316 | 3.12 | 2.16 |

| 6 X 5 | 6-5/8 | 5-5/8 | 5-1/16 | 10 | 14 | Slotted | 1-1/2 | 4-3/8, 4-1/2 | 2 | .25 | 68.3 | .0395 | 75.1 | .0435 | 4.73 | 2.96 |

| 7 X 5 | 7-5/8 | 5-5/8 | 5-1/16 | 10 | 14 | Slotted | 1-1/2 | 2-5/8, 2-11/16 | 3 | .25 | 75.8 | .0439 | 83.4 | .0483 | 5.07 | 3.03 |

| 8 X 5 | 8-5/8 | 5-5/8 | 5-1/16 | 10 | 14 | Round | 1-1/2 | 3-1/16 | 3 | .25 | 85.4 | .0494 | 93.9 | .0544 | 5.52 | 3.32 |

| 9 X 5 | 9-5/8 | 5-5/8 | 5-1/16 | 10 | 14 | Slotted | 1-1/2 | 3-1/4, 3-1/2, 3-5/8 | 3 ✽ | .25 | 97.9 | .0567 | 107.7 | .0623 | 6.00 | 3.58 |

| 10 X 5 | 10-5/8 | 5-5/8 | 5-1/16 | 10 | 14 | Slotted | 1-1/2 | 4, 4-1/8 | 3 | .25 | 113.5 | .0657 | 124.9 | .0723 | 6.73 | 3.78 |

| 11 X 5 | 11-5/8 | 5-5/8 | 5-1/16 | 10 | 14 | Slotted | 1-1/2 | 3, 3-1/8 | 4 | .25 | 127.2 | .0736 | 139.9 | .0766 | 7.26 | 4.10 |

| 12 X 5 | 12-5/8 | 5-5/8 | 5-1/16 | 10 | 14 | Round | 1-1/2 | 3-3/8 | 4 | .25 | 143.1 | .0828 | 157.4 | .0911 | 8.37 | 4.34 |

| 8 X 6 | 8-5/8 | 6-7/8 | 6-1/16 | 10 | 14 | Slotted | 1-3/4 | 2-11/16, 3-1/16 | 3 | .25 | 124.5 | .0720 | 137.0 | .0793 | 7.69 | 4.50 |

| 9 X 6 | 9-5/8 | 6-7/8 | 6-1/16 | 10 | 14 | Slotted | 1-3/4 | 3-1/2, 3-5/8 | 3 | .25 | 135.9 | .0786 | 149.5 | .0865 | 8.00 | 4.60 |

| 10 X 6 | 10-5/8 | 6-7/8 | 6-1/16 | 10 | 14 | Slotted | 1-3/4 | 4, 4-1/8 | 3 | .25 | 150.4 | .0870 | 165.4 | .0957 | 9.78 | 4.83 |

| 11 X 6 | 11-5/8 | 6-7/8 | 6-1/16 | 10 | 14 | Slotted | 1-3/4 | 2-7/8, 3 | 4 | .25 | 173.4 | .1003 | 190.7 | .1104 | 8.71 | 5.00 |

| 12 X 6 | 12-5/8 | 6-7/8 | 6-1/16 | 10 | 14 | Slotted | 1-3/4 | 3-1/4, 3-3/8 | 4 | .25 | 185.4 | .1073 | 203.9 | .1180 | 9.08 | 5.52 |

| 13 X 6 | 13-5/8 | 6-7/8 | 6-1/16 | 10 | 14 | Round | 1-3/4 | 3-5/8 | 4 | .25 | 203.8 | .1179 | 224.2 | .1297 | 10.13 | 5.60 |

| 14 X 6 | 14-1/4 | 6-7/8 | 5-7/8 | 10 | 14 | Round | 1-3/4 | 3 | 5 | .25 | 198.3 | .1147 | 218.1 | .1262 | 10.53 | 7.60 |

| 10 X 7 | 10-5/8 | 8 | 7-1/16 | 10 | 14 | Slotted | 2 | 4, 4-1/8 | 3 | .3125 | 219.4 | .1270 | 241.3 | .1397 | 10.31 | 5.70 |

| 11 X 7 | 11-5/8 | 8 | 7-1/16 | 10 | 14 | Round | 2 | 3 | 4 | .3125 | 234.2 | .1355 | 257.6 | .1491 | 10.41 | 6.07 |

| 12 X 7 | 12-5/8 | 8 | 7-1/16 | 10 | 14 | Slotted | 2 | 3-1/4, 3-3/8 | 4 | .3125 | 248.2 | .1436 | 273.0 | .1580 | 11.82 | 6.54 |

| 13 X 7 | 13-5/8 | 8 | 7-1/16 | 10 | 14 | Round | 2 | 3-5/8 | 4 | .3125 | 284.4 | .1646 | 312.8 | .1810 | 12.16 | 6.80 |

| 14 X 7 | 14-5/8 | 8 | 7-1/16 | 10 | 14 | Round | 2 | 3 | 5 | .3125 | 301.9 | .1747 | 332.1 | .1922 | 12.38 | 7.20 |

| 15 X 7 | 15-5/8 | 8 | 7-1/16 | 10 | 14 | Round | 2 | 3-1/4 | 5 | .3125 | 331.4 | .1918 | 364.5 | .2110 | 15.13 | 8.50 |

| 16 X 7 | 16-5/8 | 8 | 7-1/16 | 10 | 14 | Slotted | 2 | 2-5/8, 2-7/8 | 6 | .3125 | 346.5 | .2005 | 381.2 | .2206 | 16.14 | 9.10 |

| 18 X 7 | 18-5/8 | 8 | 7-1/16 | 10 | 14 | Round | 2 | 3-1/8 | 6 | .3125 | 396.7 | .2296 | 436.4 | .2525 | 18.25 | 10.30 |

| 20 X 7 | 20-5/8 | 8 | 7-1/16 | 10 | 14 | Round | 2 | 3-1/2 | 6 | .3125 | 433.3 | .2508 | 476.6 | .2758 | 20.27 | 11.40 |

■ Tapco recommends using WL (water level) fill + 10% for usable capacity. A gross capacity figure is no longer provided as it is inappropriate for rating an agricultural elevator bucket.

✽ Two extra holes on 3.5 centers are provided to accommodate Universal Industries standard four hole pattern

Style:

CC Digger

Design:

High speed centrifugal discharge.

Material:

Carbon Steel or Stainless Steel.

Method of Manufacture:

Fabricated.

Standard Construction:

The CC style digger bucket utilizes a 4-piece design consisting of two end plates, pressed formed body, and wear lip. Please note that there is no taper on the sides of the bucket. The ends are continuously welded on the outside.

Construction Options:

AR plating or hard bead weld.

Material Thickness:

Carbon: 12 ga., 10 ga., Stainless: 12 ga., 14 ga.

Standard Drilling:

No Charge.

Venting:

Venting available on request, contact Tapco for recommendations.

Usable Capacity:

Net or usable capacity could range from 10% to 20% above water level. For engineering purposes Tapco recommends using WL (Water Level) + 10% for usable capacity. SPACING: Minimum bucket spacing has historically been nominal projection plus 2". Many style CC buckets, however, are being used at projection plus 1", and some even closer. For engineering purposes Tapco recommends using nominal projection plus 2".

Spacing:

Minimum bucket spacing has historically been nominal projection plus 2". Many style CC buckets, however, are being used at projection plus 1", and some even closer. For engineering purposes Tapco recommends using nominal projection plus 2".

Interchangeability:

Can be intermixed with existing fabricated and nonmetallic CC style buckets. If different weight buckets are mixed in, some care should be taken that the leg does not become too far out of balance. Check elevator for proper clearances. Contact Tapco for recommendations.

Installation:

Fanged elevator bolts and nylon insert lock nuts are recommended for pulleys 6" in diameter and over. No. 3 Eclipse slotted head elevator bolts are recommended for pulleys under 6" in diameter. Flat steel washers must be placed inside the bucket under the nuts. Check elevator for proper clearances.

Caution:

Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion.