ACS Elevator Bucket

Fabricated Steel

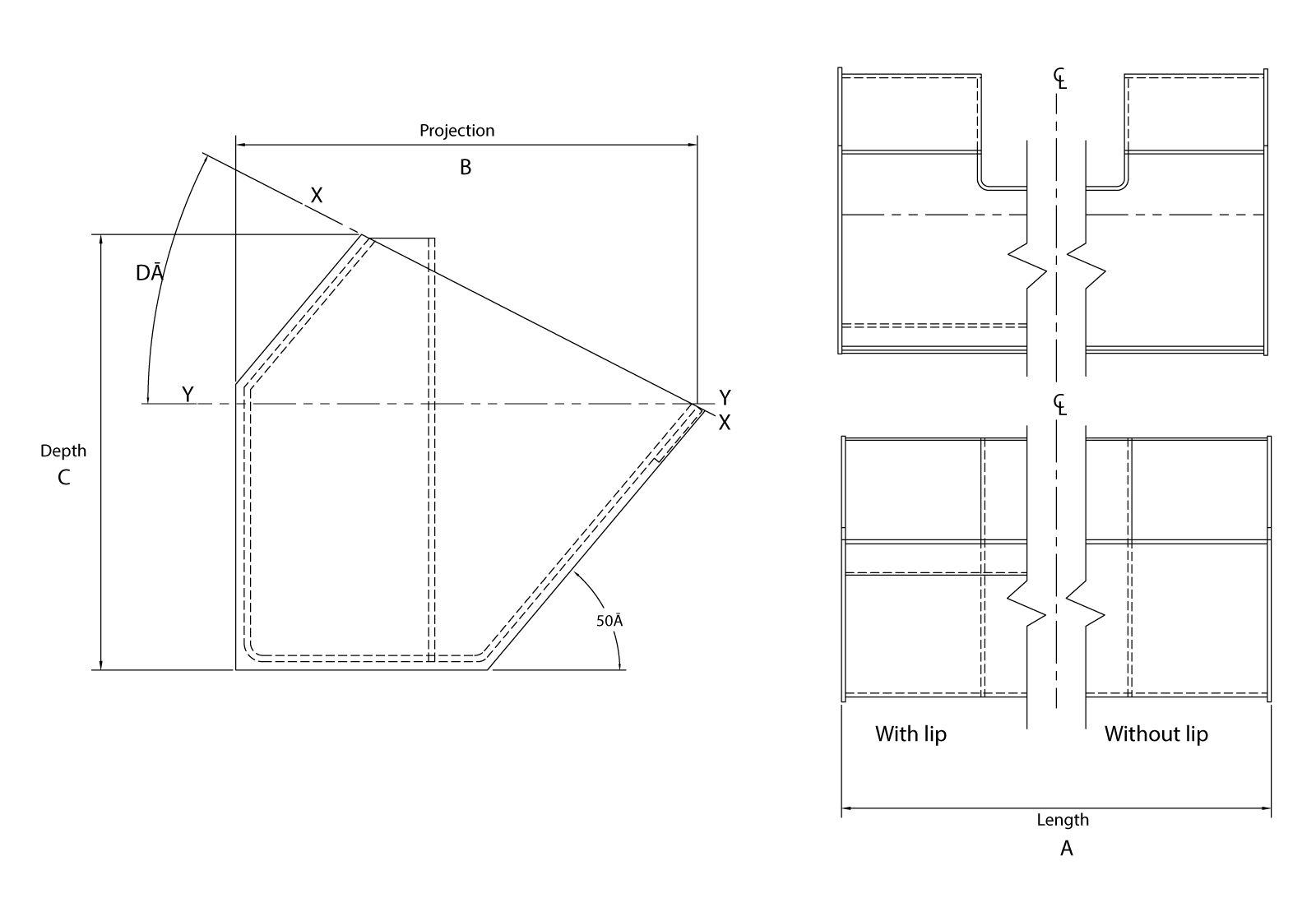

These continuous elevator buckets feature slow-speed, centrifugal discharge. Their three-piece, welded design is fully welded outside and partially welded inside.

Why Steel?

Steel buckets should be substituted for nonmetallic buckets when the heat becomes too excessive or when the bucket elevator carries extremely sharp products.

Features

The high front and the saddlebag or wrap-around features increase capacity, while the hooded back permits closer bucket spacing on chain.

Available in Stainless Steel and Carbon Steel.

Applications

- Stone

- Foundry Sand

- Sand and Gravel

- Coal

- Fertilizers

- Clay

- Salt

Measurement Conversion: Imperial Metric

| Size (Nominal) Inches |

Dimension-Actual (Inches) Tolerance A, B & C ± .25" |

Weight, Pounds (Est.) | Capacity ■ Tolerance ± 3% |

||||||

|---|---|---|---|---|---|---|---|---|---|

| Length A |

Proj. B |

Depth C |

Degree D |

Steel (.1875") | Aluminum (.1875") |

Gross X-X Cu. Ft. |

Y-Y Cu. Ft. |

||

| With Lip | w/o Lip | ||||||||

| 14 X 12 X 11 | 14 | 12 | 11-3/8 | 26 | 36 | 32 | 15.3 | .53 | .37 |

| 16 X 12 X 11 | 16 | 12 | 11-3/8 | 26 | 39 | 35 | 17.2 | .62 | .44 |

| 18 X 12 X 11 | 18 | 12 | 11-3/8 | 26 | 42 | 37 | 19.0 | .71 | .51 |

| 21 X 14 X 13 | 21 | 14 | 13-3/8 | 28 | 56 | 51 | 25.3 | 1.08 | .78 |

| 24 X 14 X 13 | 24 | 14 | 13-3/8 | 28 | 62 | 56 | 27.3 | 1.28 | .93 |

| 27 X 15 X 13 | 27 | 15 | 13-3/8 | 21 | 72 | 65 | 32.3 | 1.62 | 1.29 |

| 30 X 15 X 13 | 30 | 15 | 13-3/8 | 21 | 84 | 77 | 37.3 | 1.84 | 1.47 |

■ Tapco recommends using gross x .75, for usable capacity

Style:

ACS

Design:

Slow Speed Centrifugal discharge.

Material:

Carbon Steel, Stainless Steel, Aluminum.

Method of Manufacture:

Fabricated.

Standard Construction:

The ACS style bucket utilizes a 3- piece design consisting of two end plates, and body. All seams are continuously welded outside and partially inside. The bucket will be produced after Tapco supplies a CAD drawing to be approved by customer.

Construction Options:

AR plate, wear lips, hard bead welds, or bearing plates.

Material Thickness:

7 ga. (3/16”), 1/4”, 5/16”, 3/8”, and 1/2”.

Standard Drilling:

No charge for standard belt or chain drillings.

Venting:

Available on request. Contact Tapco for recommendations.

Usable Capacity:

Tapco recommends using 75% of gross, (100%) capacity

Spacing:

Contact Tapco for recommendations.

Interchangeability:

Can be intermixed with existing fabricated ACS style buckets. If different weight buckets are mixed in, some care should be taken that the leg does not become too far out of balance. Check elevator for proper clearances. Contact Tapco for recommendations.

Installation:

Use Grade 5 hex head bolts with hex nuts, flat washers, and lock washers. Elevator bolts should not be used on chain attachments.

Caution:

Welding and cutting on elevator legs without taking proper precautions is extremely dangerous and can cause a violent explosion.